Joe Evans, Ph.D

http://www.pumped101.com

INTRODUCTION

Definition & Description

By definition, a centrifugal pump is a machine. More specifically, it is a machine that imparts energy to a fluid. This energy infusion can cause a liquid to flow, rise to a higher level, or both.

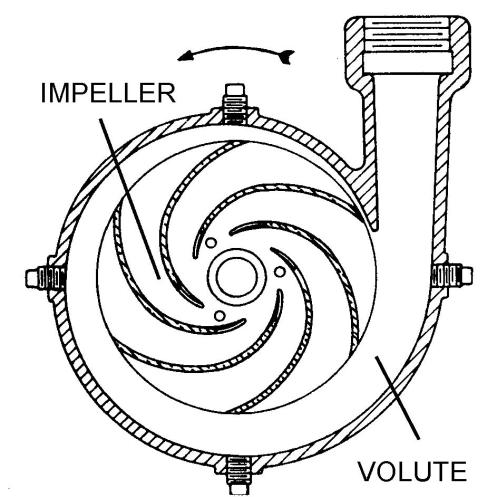

The centrifugal pump is an extremely simple machine. It is a member of a family known as rotary machines and consists of two basic parts: 1) the rotary element or impeller and 2) the stationary element or casing (volute). The figure at the top of the following page is a cross section of a centrifugal pump and shows the two basic parts.

Figure 1

The centrifugal pump’s function is as simple as its design. It is filled with liquid and the impeller is rotated. Rotation imparts energy to the liquid causing it to exit the impeller’s vanes at a greater velocity than it possessed when it entered. This outward flow reduces the pressure at the impeller eye, allowing more liquid to enter. The liquid that exits the impeller is collected in the casing (volute) where its velocity is converted to pressure before it leaves the pump’s discharge.

A Very Brief History

The centrifugal pump was developed in Europe in the late 1600’s and was seen in the United States in the early 1800’s. Its wide spread use, however, has occurred only in the last seventy-five years. Prior to that time, the vast majority of pumping applications involved positive displacement pumps.

The increased popularity of centrifugal pumps is due largely to the comparatively recent development of high speed electric motors, steam turbines, and internal combustion engines. The centrifugal pump is a relatively high speed machine and the development of high speed drivers has made possible the development of compact, efficient pumps.

Since the 1940's, the centrifugal pump has become the pump of choice for many applications. Research and development has resulted in both improved performance and new materials of construction that have greatly expanded it's field of applicability. It is not uncommon today to find efficiencies of 93%+ for large pumps and better than 50% for small fractional horsepower units.

Modern centrifugal pumps have been built to meet conditions far beyond what was thought possible fifty to sixty years ago. Pumps capable of delivering over

1,000,000 gallons per minute at heads of more than 300 feet are common in the nuclear power industry. And, boiler feed pumps have been developed that deliver 300 gallons per minute at more than 1800 feet of head.

THEORY

In operation, a centrifugal pump “slings” liquid out of the impeller via centrifugal force. Now centrifugal force, itself, is a topic of debate. Although I will not go into detail here, it is considered by many, including myself, to be a false force. For our purposes here, we will assume that it is a real force. Refer to the “False Force Puzzler” for more information.

Centrifugal Force

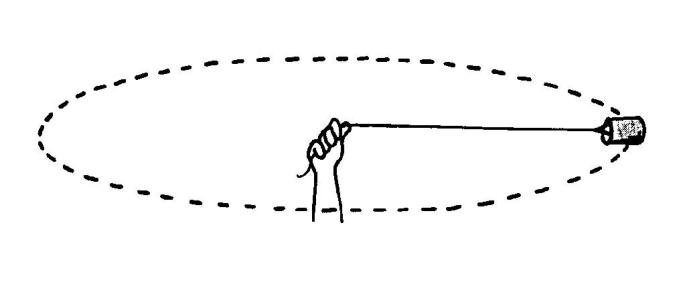

A classic example of the action of centrifugal force is shown below. Here, we see a pail of water swinging in a circle. The swinging pail generates a centrifugal force that holds the water in the pail.

Figure 2

Now, if a hole is bored in the bottom of the pail, water will be thrown out. The distance the stream carries (tangent to the circle) and the volume that flows out (per unit time) depends upon the velocity ( in ft/sec) of the rotating pail. The faster the pail rotates the greater the centrifugal force and therefore the greater the volume of water discharged and the distance it carries.

The description above could be considered that of a crude centrifugal pump (sans volute of course). It demonstrates that the flow and head (pressure) developed by a centrifugal pump depends upon the rotational speed and, more precisely, the peripheral velocity of its impeller (pail).

Peripheral Velocity & Head

Gravity is one of the more important forces that a centrifugal pump must overcome. You will find that the relationship between final velocity, due to gravity, and initial velocity, due to impeller speed, is a very useful one . If a stone is dropped from the top of a building it's velocity will increase at a rate of 32.2 feet per second for each second that it falls. This increase in velocity is known as acceleration due to gravity. Therefore if we ignore the effect of air resistance on the falling stone, we can predict the velocity at which it will strike the ground based upon its initial height and the effect of acceleration due to gravity. The equation that describes the relationship of velocity, height, and gravity as it applies to a falling body is:

v2 = 2gh

Where:

v = The velocity of the body in ft/sec

g = The acceleration due to gravity @ 32.2 ft/sec/sec (or ft/sec2)

h = The distance through which the body falls

For example if a stone is dropped from a building 100 feet high:

v2 = 2 x 32.2 ft/sec2 x 100 ft

v2 = 6440 ft2/sec2

v = 80.3 ft/sec

The stone, therefore, will strike the ground at a velocity of 80.3 feet per second.

This same equation allows us to determine the initial velocity required to throw the stone to a height of 100 feet. This is the case because the final velocity of a falling body happens to be equal to the initial velocity required to launch it to height from which it fell. In the example above, the initial velocity required to throw the stone to a height of 100 feet is 80.3 feet per second, the same as its final velocity.

The same equation applies when pumping water with a centrifugal pump. The velocity of the water as it leaves the impeller determines the head developed. In other words the water is “thrown” to a certain height. To reach this height it must start with the same velocity it would attain if it fell from that height.

If we rearrange the falling body equation we get:

h = v2/2g

Now we can determine the height to which a body (or water) will rise given a particular initial velocity. For example, at 10 Ft per Sec:

h = 10 ft/sec x 10 ft/sec / 2 x 32.2 ft/sec

2

h = 100 ft2/sec2 / 64.4 ft/sec2

h = 1.55 ft

If you were to try this with several different initial velocities, you would find out that there is an interesting relationship between the height achieved by a body and its initial velocity. This relationship is one of the fundamental laws of centrifugal pumps and we will review it in detail a little later. As a finale to this section, let's apply what we have learned to a practical application.

Problem: For an 1800 RPM pump, find the impeller diameter necessary to develop a head of 200 feet.

First we must find the initial velocity required to develop a head of 200 feet:

v2 = 2gh

v2 = 2 x 32.2 ft/sec2 x 200 ft

v2 = 12880 ft2/sec2

v = 113 ft/sec

We also need to know the number of rotations the impeller undergoes each second:

1800 RPM / 60 sec = 30 RPS

Now we can compute the number of feet a point on the impellers rim travels in a single rotation:

113 ft/sec / 30 rotations/sec = 3.77 ft/rotation

Since feet traveled per rotation is the same as the circumference of the impeller we can compute the diameter as follows:

Diameter = Circumference /

Diameter = 3.77 Ft / 3.1416

Diameter = 1.2 Ft or 14.4 In

Therefore an impeller of approximately 14.4" turning at 1800 RPM will produce a head of 200 Feet.

It just so happens that water, flowing from the bottom of a tank, follows the same rules. See the “Up and Down Puzzler” to understand how.