| RC Worst & Co. Inc. started building packaged lift stations over twenty years ago providing clients a plug and play solution. In the last year RC Worst & Co. made the decision to allocate resources to overhaul the entire Automated Flow Systems line of packaged lift stations using Solidworks 3D modeling.

3D modelling allows our designers to produce an innovative product more efficiently. Clients including engineers, operators, municipalities, contractors, and developers are already experiencing the benefits of the updates.

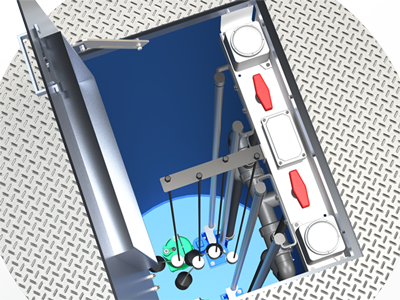

Recently we completed an AFS packaged lift station for a project in the greater Boise, ID area. Our engineer used modelling techniques to update one of the innovate features developed by RC Worst & Co. now called the Operations Deck. The Op Deck places electrical junction boxes and valve operators where they can be easily accessed by operators. Since implementation the concept has been a huge success with designers and field personnel alike.

The 3D model facilitated seamless communication with the fabrication shop getting stainless steel material laser cut and bent precisely allowing flawless assembly. Our shop technicians used 3D details for assembly making their task straight forward.

We find our Automated Flow Systems packaged lift stations include several benefits such as superior design, water-tight construction, a complete package, and quick installation. Using 3D modelling will continue to allow RC Worst & Co. to bring innovation to their line of Automated Flow Systems packages.

|

|

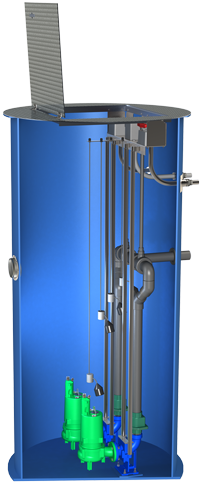

3" AFS Lift Station

3" AFS Lift Station

3" Lift Station Internals

3" Lift Station Internals

3" Lift Station Hatch View

3" Lift Station Hatch View